-

Your solutionsYour solutions

Intralogistics Solutions Provider

- Industries

-

Applications

- Automation

-

Lithium-ion technology

Lithium-ion technology

Your solutions

-

Case studies

Your solutions

-

ProductsProducts

Intralogistics Solutions Provider

-

New Forklifts

New Forklifts

Products

-

Rental Forklifts

Rental Forklifts

Products

- Used Forklifts

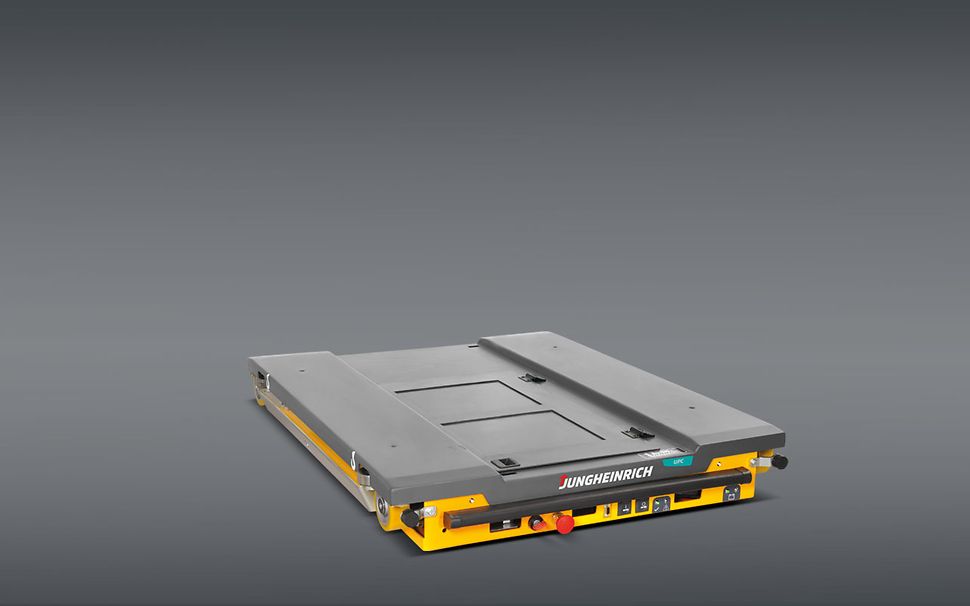

- Automated components

-

Batteries / Charging Technology

Batteries / Charging Technology

Products

-

Batteries

-

Charging technology

Charging technology

Batteries / Charging Technology

-

Batteries

- Racking / Warehouse Storage

-

Digital products

-

Special builds

Products

- Radio data transmission

-

Operating Manuals

Products

-

New Forklifts

-

SystemsSystems

Intralogistics Solutions Provider

-

System supplier

Systems

- Driverless Transport Systems

- Conveyor systems

-

Automated Storage / Retrieval System

Automated Storage / Retrieval System

Systems

-

Automatic pallet warehouse

Automatic pallet warehouse

Automated Storage / Retrieval System

-

Automated miniload warehouse

Automated miniload warehouse

Automated Storage / Retrieval System

- Dynamic small parts storage

-

Automatic pallet warehouse

- Storage systems

- Software / IT-systems

-

System supplier

-

ServicesServices

Intralogistics Solutions Provider

- Rental

- Genuine spare parts

- After Sales Services

-

Energy management

Services

-

Automatic systems

Services

-

Call4Service

Services

- Health / Safety

-

Operating manuals

Services

-

About usAbout us

Intralogistics Solutions Provider

-

Jungheinrich Malaysia

About us

- Stories

- Innovation & Aspiration

- Sustainability

-

Careers

About us

-

Press / Events

About us

-

Certificates

About us

-

Location finder

About us

-

Jungheinrich Malaysia

-

Online Shop